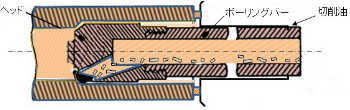

Deep Hole Drilling (BTA System)

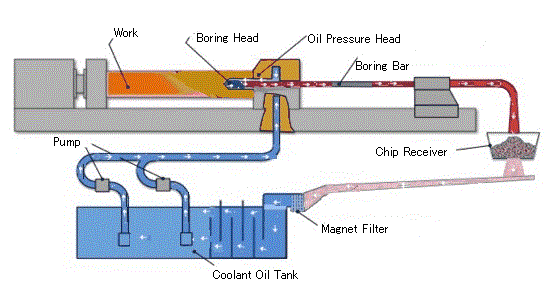

As shown below, the high-pressure cutting oil pressurized by the pump is sent to the pressure head which is in contact with the workpiece, it reaches the cutter head through the gap between the drilled hole and the boring bar. Chips were pass through the inside of boring bar and go back to the tank through the chip receiver and the magnetic filter.

◆Installed Deep Hole Drilling Machine (BTA SYSTEM)

Type B400 Large Deep Hole Drilling Machine

Type B150 Mid size Deep Hole Drilling Machine

Type B300 Large Deep Hole Drilling Machine

Enlarging of Inner Surface of Steel Pipe

Type KB150 Eccentric Deep Hole Drilling Machine

◆Excellent feature of Deep Hole Drilling Machine

- It is suitable for heavy duty machining

The deep hole drilling of BTA System is suitable for not only small diameter but also large deep drilling by using a pipe named boring bar with strong resistance to twist and processing with a head with high rigidity.

- Head with high straightness

The cutting head attached to the boring bar is doing a good job. It strikes the work which rotates at high speed and cuts with a cutting edge (carbide tip or blade). Cutting oil supplied from the pressure head is supplied from the gap between the head and the workpiece, sweeps the chips, passes through the boring bar and is discharged, maintaining good machining accuracy.

- Head Type

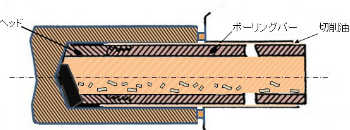

◆Solid Boring Processing

It is used for when drilling holes in solid material by general processing method. All parts of the hole will become chips. In the figure, chips discharged through the inside of the boring bar are displayed in small strips.

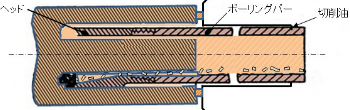

◆Trepaning processing

It is used when drilling large diameter holes in the material. A dedicated head for deep hole processing is used leaving the center part (core material) of the hole.

◆Counter boring processing

It is used for hole expansion processing of materials already having holes in the material or pipes. It is also used when surface roughness and accuracy are required.

Large size boring bar

Various heads

Solid Boring Head

Trepaning Head

Counter Boring Head

◆Movies being processed

Materia:SACM645, 4,100mm Length Solid Bar

>

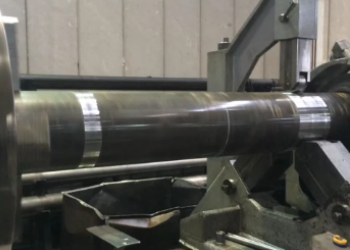

Material:STKM13A Enlarging of Inner Diameter of Steel Pipe

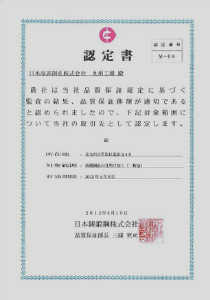

◆Certificate

- Quality certificate documents etc.

Although we have not acquired ISO 9001, we are auditing factories based on our own quality assurance manual and quality assurance system.

TOSHIBA Corporation

Nippon Yakin Kogyo Co., Ltd.

Hitachi Metals Ltd.

JAPAN CASTING & FORGING CORP.